Challenge

To develop a precision analog current source output using OpenECU’s M670, to be utilized as a control source for precise force control of solenoids for developing transmission control strategies.

The continued push by OEMs for increased fuel economy has driven the market to develop automatic transmissions with an increasing number of gears. Recent designs make use of 11 or more speeds in new or upcoming transmissions. In order to be able to address the need for our customers to implement smooth and efficient transmission controls, Dana provides a constant current drive feature on the M670 OpenECU™ module.

Solution

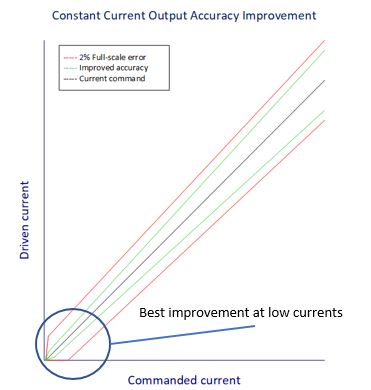

Dana’s OpenECU M670 was applied for a specific application where precision current control was needed to develop a prototype transmission control algorithm. Dana’s standard, off-the-shelf OpenECU hardware and software was designed to have sufficient flexibility so that an option control could be implemented to tailor the range and resolution of the constant current outputs along with a zero-current offset compensation algorithm and software to meet the precise needs of customers. This customer’s application development requirements were satisfied with a customer specific option control hardware configuration. OpenECU option control M670B-00Z utilized components with tighter value tolerance to achieve the desired accuracy.

Results and Impact

Dana’s engineering team worked closely with the customer to develop M670B-00Z to meet their specific application needs. The development work performed using the OpenECU M670B-00Z led to the successful implementation of an analog constant current source with sufficient range and accuracy to meet the needs of the customer’s development effort.

Available on up to 8 output pins, this feature makes use of an Infineon TLE8242 device to high accuracy (+/- 2% full scale error over temperature when autozero is used) constant current drive with feedback control and a range of up to 2.4A per channel (range configurable in hardware). OpenECU platform software provides the necessary MATLAB Simulink library blocks to configure, drive and monitor the module outputs directly on the M670. Because the interface to the constant current driver outputs is model based, the customer can focus their expertise on the high-level transmission application while relying on the hardware and platform software implementation from Pi.