Production Variants – Customizing OpenECU hardware for specific system requirements or cost optimization

Dana offers a wide variety of off the shelf modules that can fulfill the requirements of a broad range of applications. In some cases, there is a need to modify the off-the-shelf ECU to optimally work with specific sensors or actuators. In other cases, only a portion of the I/O is utilized to meet the requirements. In both cases, Dana offers the ability to customize existing off-the shelf ECUs to provide the most cost-effective solutions for production applications. We refer to these customized ECUs as production “variants”.

What is a production variant?

A production variant of an OpenECU module is very similar to an option control, except the circuit population changes are done at the factory during production. See the Part I of this Blog, “Option Controls” for information on how Pi develops option controls. As a short summary, Dana can provide development units with circuit changes implemented in our engineering lab to meet the needs of a customer’s system. A production variant is designed to be used as a production ECU, instead of just a development unit. The production aspect can allow for cost savings and would be PPAP capable.

How is a production variant developed?

There are two main avenues for how a variant OpenECU can be developed. The first, which is the usual case, is that they start out as an option control. When a customer has been using option control units finds that there will be a need for many more modified versions of the ECUs (possibly because they are going into production), Dana will work with them to create a variant. At that point, the development work for the customer’s system integration is done and the ECU modification needs to be released to our factory to produce the units directly. After that, ordering new ECUs with the modification can be streamlined.

The second avenue is directly developing a production variant. Dana will work with the customer to specify the variant directly when needs for low to mid volumes are apparent. Specific requirements and needs will be discussed and Dana will work with the customer to come up with the best solution for their system. After specification, Dana will create engineering samples to be tested on system to avoid “gotcha’s” (surprise changes based on unknown system elements) before releasing the variant to be produced in volume at the factory.

Production variant vs. Option control

Production variants are normally created when volumes above 50 are needed. Option controls are usually only development units from 1 to 50 pieces.

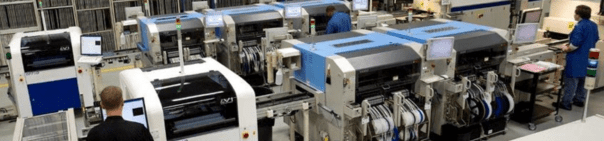

Production variants are made directly at the factory, instead of being modified at Dana. Since production variants are built at the factory they usually can be lower cost than modified off-the-shelf ECUs. Cost savings are from reduction in hand modification after the SMT process and potentially from removing compements not needed from the off-the-shelf version. Also, production variants can go through the PPAP process, while option controls cannot.

Variants will have some associated NRE for development, testing, and releasing of the variant part build documentation, but the costs are offset by lower per-unit cost vs. option controls, especially for low to mid volumes.

How it has been done before:

See case-study “Providing a new production EV supervisory controller with a customized M560”